Vestlandskyss can generate a lot of electricity. She has three fixed solar panels, a tow-generator when sailing, and an upgraded engine alternator when motoring. Despite that, it was clear that the house batteries weren’t getting as much charge as we would expect, while the yacht was bobbing unattended on her mooring.

Of the solar panels, one is a flexible on the bimini hood that I have wired purely as a top-up for the cranking battery. We have some additional ‘briefcase style’ panels that can be mounted on deck at anchor, but most of the power generation is by two solid panels on either side of the cockpit. These can lie flat against the stanchions, but are swivelled out to face the sun when in use.

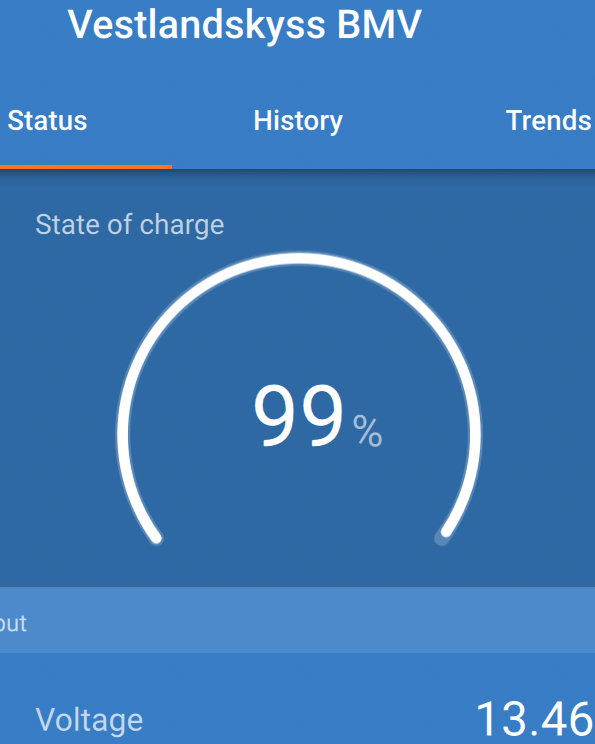

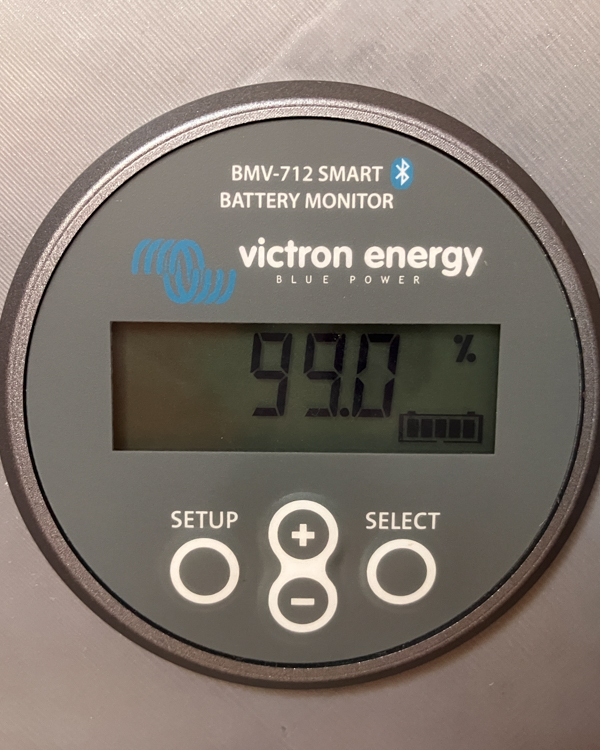

Each of our solar panels runs through one of three Victron MPPT controllers, and the total state of the system is aggregated and output onto a display. Every morning, when I get up to put on the coffee, one of my first checks is on the state of the batteries. Usually they are showing less than 100% charge because there are systems, such as the fridge and masthead lights, that run overnight, but in addition the MPPT controller calculates in real time the current going into and out of the house batteries.

On this particular morning, the sun was shining but there was no sign of any recharging. I checked the output from the controller, and there was nothing. I checked the joined output from the two cockpit panels, and again there was nothing.

Since both panels appeared to have failed at once – a very unlikely coincidence -I connected one of our spare briefcase panels in to the circuit, and the controller started up and behaved normally. The controller was fine. How could both cockpit panels have failed simultaneously?

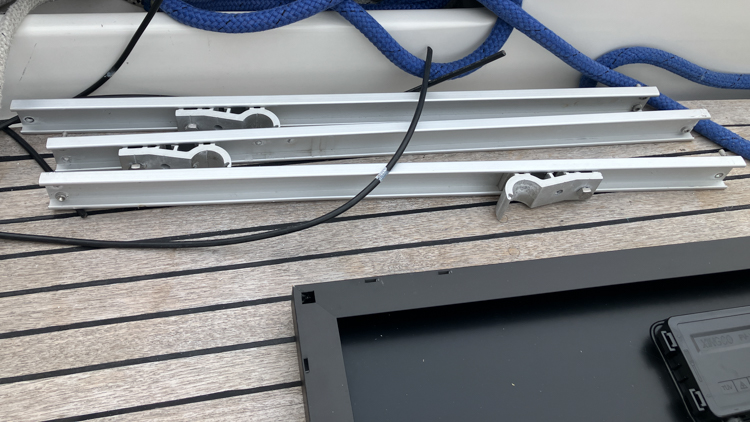

I wanted to have a look at the connector box on the port side panel, but unfortunately it was occluded by the mounting rail, so I had to remove the rails and dismount the panel. This was a nerve-wracking task, because the mounting rails are comprised of a number of small fiddly pieces, and if I dropped one, it would fall irretrievably into the ocean. As it was, I successfully retained all the clamp parts, but lost a screwdriver overboard.

Once dismounted, I opened the connector box expecting to find some signs of, I don’t know, heat stress or rust or lightning strike, but there was nothing interesting to see at all. There were just a couple of diodes which tested out just fine, and some nice clean soldering.

The sun was shining, and the remaining starboard panel should have been generating oodles of power. I couldn’t get to the connector box, again because of the mounting rails, so I measured the voltage at the untidy nest of MC4 connectors in the lazarette. Still nothing.

I do dislike MC4 connectors. They have become the world standard for solar arrays both on land and at sea. They are supposed to be (a) weather resistant, and (b) secure but easy to unplug. In my experience, they are neither. I don’t know which small child’s fingers were used as a model by the designer, but even my slender fingers are far too big to work the spring release. When I work with MC4s, I usually end up bleeding.

It wasn’t until I had dismounted the starboard panel that I discovered at least part of the problem. Salt water had got into one of the starboard MC4s where it crossed from the panel to the deck gland, and corrosion had been slowly rotting its way along the cables. The starboard panel was most likely still working, but the current wasn’t getting out through the corroded connectors.

For some time, it seemed, we had only been operating on the port panel, and now this too had failed.

There’s nothing quite like salt water creeping along a copper wire, it is amazing to behold. I chased the rot along the cable for several metres, and then chopped out an additional metre for good measure. Thankfully there is a fair bit of spare cable aboard, and a number of unused MC4 connectors, to make good the lost sections.

Looking online for new solar panels, I could buy something the same physical size but with a modern, higher wattage (for a price!), or I could stick with 120 watts but with upgraded efficiency. These latter were only $200 per panel from Alvolta, delivered to the marina, so the deal was done.

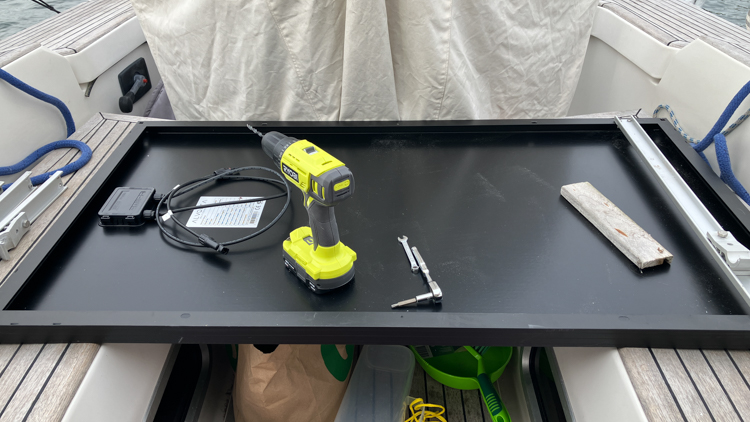

Peter from the marina helped me to get the new panels out to the mooring in his tinny, and then it took a bit of juggling to fit the unwieldy great things into place.

Thankfully, the new solar panels were several kilos lighter than the old ones, but there was still a heart-in-mouth moment where each one was balanced on the rail while I tried to secure the five loose and irreplaceable parts of each clamp mechanism above the unforgiving deep.

But then the job was done, and the sun came out.

The batteries charged right up.

It was time to go sailing…