While backing the yacht out of her berth the other weekend, the engine overheated. It had already done this once recently, and on that occasion had filled the bilge with oil. I had since carefully (and expensively) replaced all of the metal oil pipes in case of invisible pinholes, and since then the engine had been behaving itself, so it was disconcerting to hear the alarm shrieking again. This time, before we killed the motor, I peeked over the stern to check the exhaust, and sure enough it was running dry. There was something amiss with the raw water cooling pump.

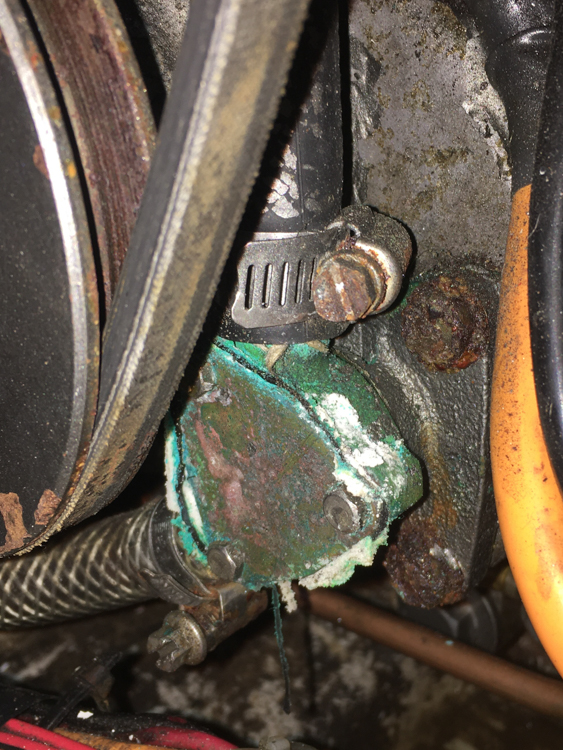

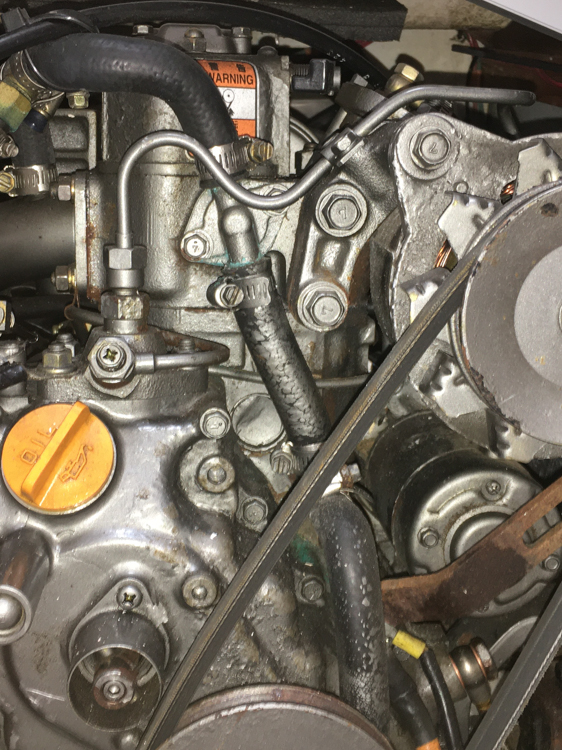

With the engine cover removed, I could see that the cover to the pump’s impeller housing was now streaked with green, which it hadn’t been before. Clearly it was now leaking sea water, but it is well known on the Yanmar 1GM10 that a leaky pump cover can drip subtly and almost invisibly onto one of the oil lines, causing it to rust.

Perhaps this was the ultimate cause of my assumed pinhole leak? Perhaps, but a slight water drip didn’t explain my current problem. I removed the cover, expecting to find the impeller broken up into chunks, but it was still in place and in reasonably good shape. Curious.

I unfastened the clamp holding the flexible sea water inlet pipe and pulled it off the pump, forgetting that I had not first closed the through-hull. There was a violent spray of sea water which only stopped after I reached behind the engine and smacked the stopcock lever with a rubber mallet. Shaking the water out of my hair and rolling my eyes at my carelessness, I returned to the task at hand.

With the hoses disconnected, it was time to remove the pump, but this was easier said than done. Perhaps due to long-term microscopic leakage, but certainly at least in part due to long-term neglect, all three of the pump’s mounting bolts were rusty and rounded. There was nothing for a spanner to grip.

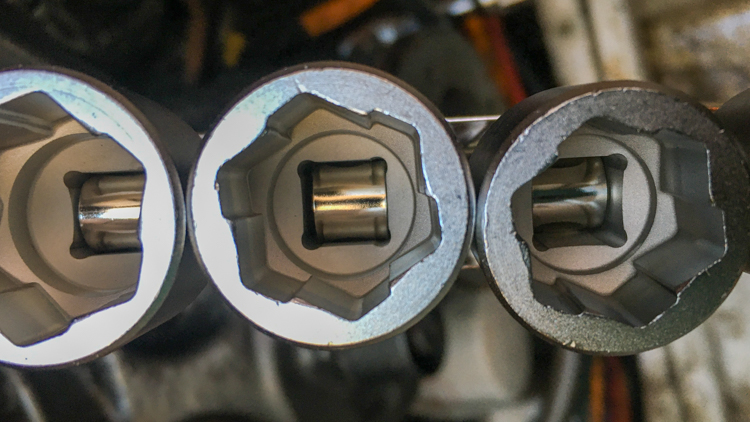

I was contemplating the traditional solutions (welding a rod to the rusty bolt head, chiselling a groove to provide purchase for an impact driver), when on the internet I discovered “bolt extractor sockets”. What a marvellous invention. They’re like a regular socket, but instead of a hex shape inside, they contain angled blades. The idea is that you hammer them onto the rounded nut or bolt so that they cut their way on and hold tight, at which point you simply undo them with a regular socket handle.

I bought a set at Repco. The kit looked solid, but the concept sounded far too easy to be true. I was wrong; the first bolt came off like a dream. After a little fiddling, so did the second one.

There is an immutable rule of mechanics, that – regardless of where you choose to start or what you are working on – it is always the final fastener that causes the most trouble. The third pump bolt was no different. I hammered home the extractor socket just fine, but the third bolt sits partially obscured by the crankshaft pulley, and my socket wrench is just a little too fat to fit between the pulley and the bolt head.

I really really didn’t want to remove the crankshaft pulley. In that direction lies madness. Instead, I went to Nubco and purchased a beautiful little socket wrench with a low profile and short handle, built especially for those awkward tight corners. Back on the boat, it slipped perfectly under the pulley, and in a jiffy out came the water pump.

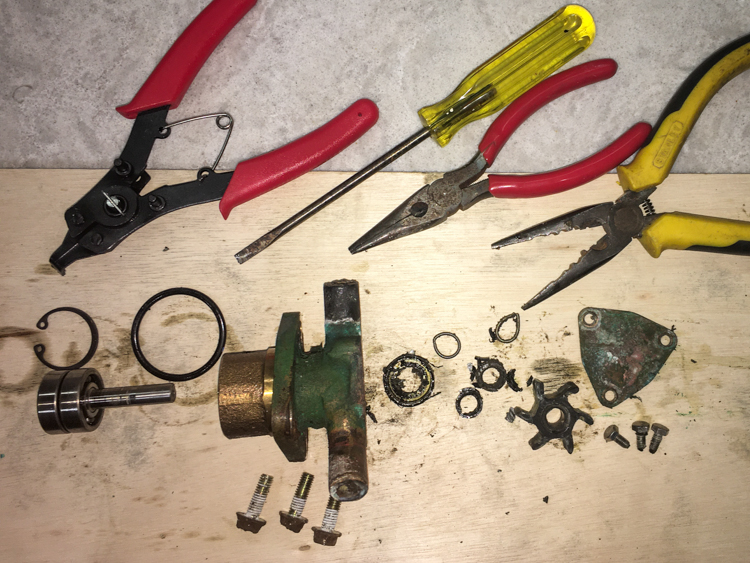

I could clearly see the moving parts inside, and frankly it didn’t look too bad. I needed to deal with the leak, but the rest looked OK. Still, there was a problem with the pump, so I went ahead and disassembled it. Most of the guts came out easily, but I had to pry and chisel the oil and water seals, and they would never work again. Nevertheless, they had looked fine before I mangled them.

I asked the lovely people at Spectrum Engineering for Yanmar’s full rebuild kit. They didn’t have one, but they carefully examined my disassembled parts, gave me back the ones that they judged unharmed, and replaced the bearings and seals from their shelves. The lady asked if I wanted a gasket for the impeller cover. I said, “what gasket?” because my pump hadn’t had one. No wonder it was leaking.

After scrubbing the old parts clean with toilet gel, vinegar, and bicarb, the rebuild was pretty simple, apart from a rookie mistake when I was drifting in the new bearing seal with the back of a socket but unaccountably got it wedged at a slight angle. Back to Spectrum to get another replacement, and then the job was done.

I’d decided to replace the seawater hoses that feed the pump, because they had seemed a bit crispy to the touch when I pulled them off. My local Repco supplied a Z-hose which I could cut into lengths including the tricky moulded curves.

Back at the boat, I laid down a puppy-training pad under the engine (marvellous for soaking up spillage, and much cheaper than posh chandlery pads) and pulled off the old seawater hoses. The stopcock was of course still closed, but residual water spilled out as I got to work replacing them, using new stainless hose clips.

Once both pump and pipes were installed, I folded up the saturated puppy-training pad, dropped it in the bin, started the bilge pump to clear the overspill, and watched the shells tumble along in the lowest bilge. Shells?

I stopped the bilge pump, and had a closer look. There was a handful of tiny mussel shells rattling around, which must have been ejected from the inlet hose when I accidentally flushed it over my head.

What the heck were shells doing in the intake hose? I remembered reaching behind the engine and whacking the stopcock lever with the mallet. There had been plenty of room to swing the hammer. I got out the Dolphin torch and peered over the engine block and into the gloom under the cockpit sole. I could clearly see the inlet hose, leading directly from the stopcock to the pump inlet; no filter, no basket, just raw seawater and whatever happened to be floating in it.

I can only imagine that the shells have been tumbling inside the hose, occasionally falling across the intake and blocking it, falling temporarily free when the engine and pump stops, ready to pop up and block the hose by random chance when the pump re-starts. I don’t want to imagine how many other shells have been crushed to fragments by the impeller and sent to circulate through the engine.

I bought and fitted a strainer, fired up the engine, and sat happily on the dock watching the salt water being pumped back into the sea.

Quite a saga. I admire your industry and the illustrative photos were excellent.

Well done mate. I wish i had the patience.